Why Surface Finish Matters in Polymer Seal Performance

Picture this: You have an application using a standard O-Ring. The O-Ring seals great, but is wearing out very quickly, and the friction is far exceeding the goals of the system.

You retrofit a fancy PTFE spring-energized seal that costs 1000 times more than the O-Ring… only to find out it leaks!

Did you get a defective seal? Is the seal designer incompetent? Is the raw material bad?

Actually, everything about the design and manufacturing of the spring-energized seal could be perfect, and you could still find yourself with leakage.

While blaming the seal might be your first instinct, the leakage, in fact, could have nothing to do with the seal itself — and everything to do with the surface finish of the hardware it’s trying to seal against.

How is Surface Finish Defined?

If you’ve seen an image of a seemingly smooth surface under a high-power microscope, you know that what looks flawless to the naked eye can actually be full of peaks, valleys, cracks, and imperfections.

These microscopic features of any surface are particularly important to sealing performance. Surface finish is a complex and in-depth subject that has many facets of analysis to describe the texture or topography of a surface.

In the world of seals, surface roughness is typically used to describe the finish condition of a sealing surface. The Roughness Average (Ra) value is the most commonly used parameter, expressed in microinches or micrometers. The lower the value, the smoother the surface.

Ra is generally used for historical or traditional purposes, and not for its merit, as it doesn’t fully define a surface. It leaves the possibility of a surface with high peaks and low valleys to still average out to a reasonable number. (Though in most modern finishing techniques, this would be an undesirable and unacceptable condition.)

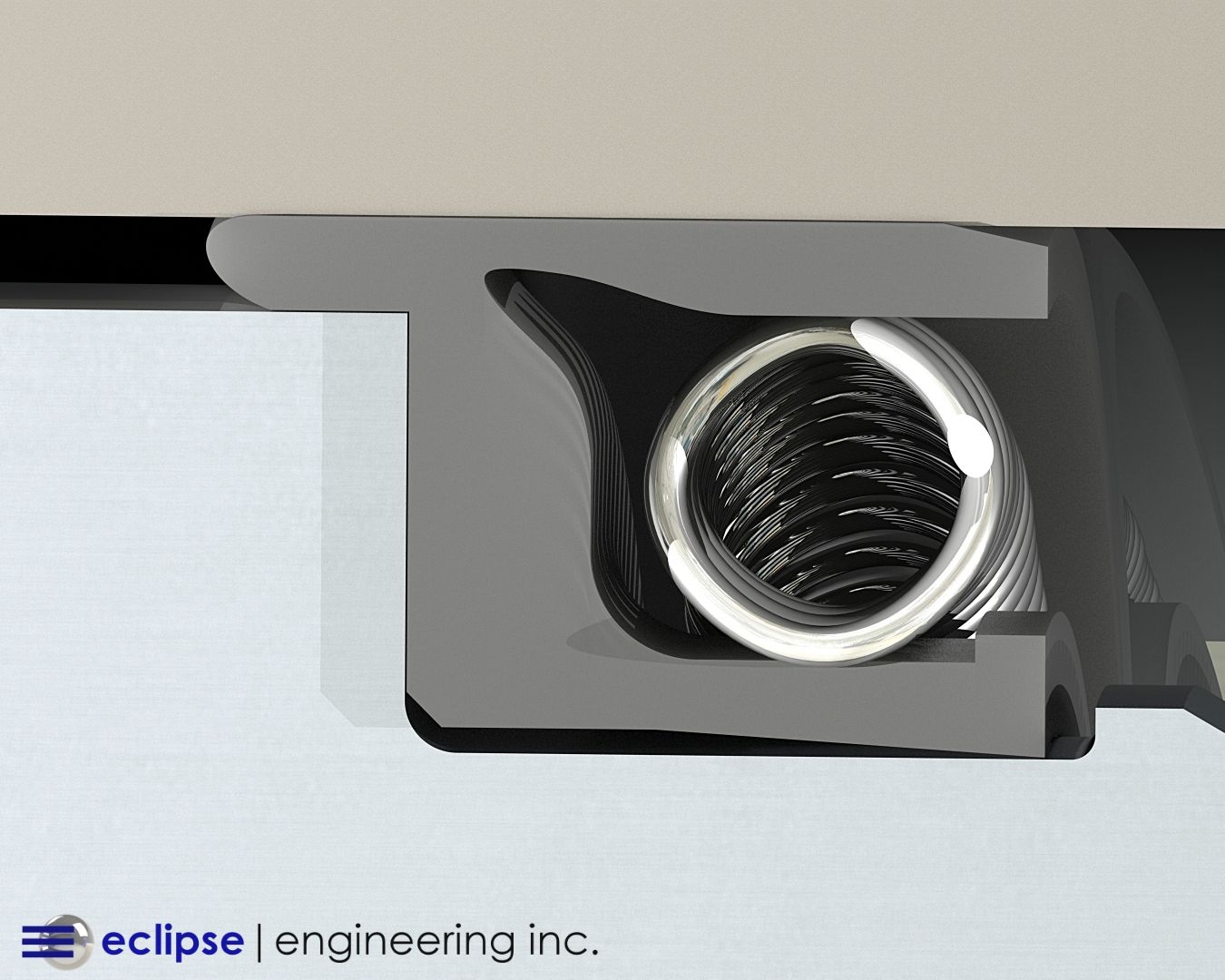

These peaks and valleys are really what matter to sealing performance, especially when using polymer-based seals. These are the microscopic gaps that the seal is responsible for closing off.

Why Surface Finish is More Critical for Polymer-Based Seals

If you’re accustomed to using O-Rings or elastomeric seals, hardware surface finish might be considered an afterthought. In many cases, an “as machined” finish will be perfectly fine for an O-Ring to seal against.

An O-Ring is much softer and more compliant than PTFE and most other polymers. A rubber-like material can easily conform to rough and uneven surfaces to provide effective sealing.

While PTFE might be considered a relatively soft plastic, it’s still many times harder than most O-Ring materials. Rather than “squishing” into a microscopic gap in the surface to seal it, a harder material will merely bridge the imparity, creating a leak path.

In most cases, surface finishes intended for an O-Ring will result in unacceptable leakage when used with a PTFE or polymer-based seal.

What Surface Finishes are Recommended for Polymer-Based Seals?

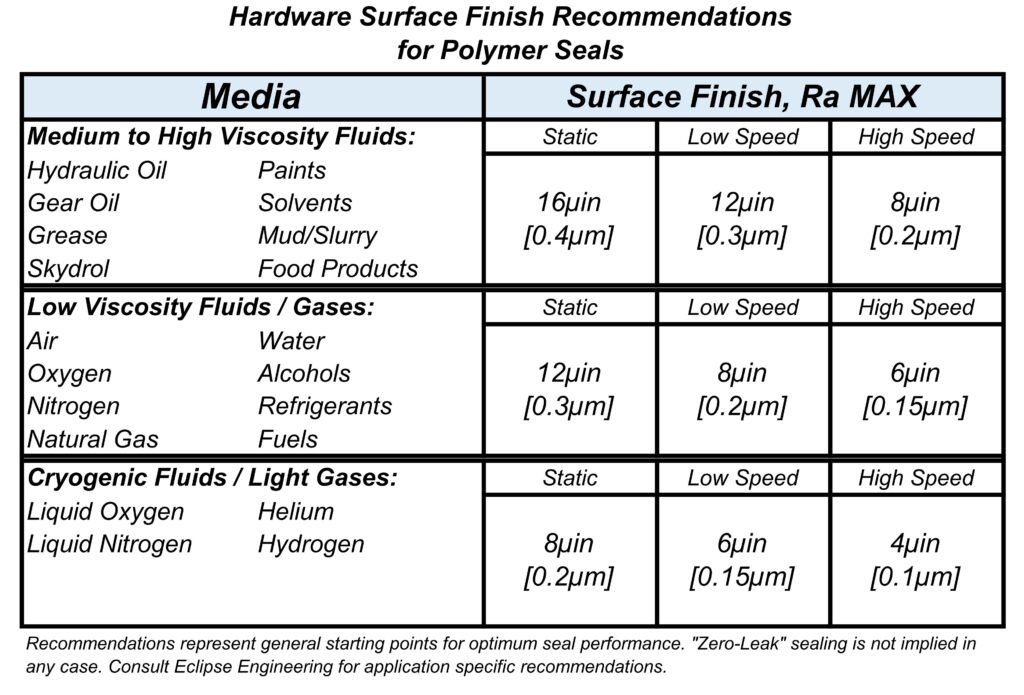

Surface finish requirements will largely be dependent on the media to be sealed and the dynamics of the system.

Recommendations for a static seal that’s meant to work in peanut butter will be very different from a reciprocating valve sealing liquid oxygen.

Below is a table with standard recommendations based on some common media and dynamic situations. These provide a general idea of the surface finishes needed, but please consult us for application-specific suggestions .

It’s important to note that the best surface finish achievable from a typical turning process is usually a 16 µin Ra. In many cases, it won’t be better than a 32 µin.

Milling operations can result in even poorer finishes. Cast surfaces are also unlikely to have finishes better than these.

This is important because, aside from sealing a very viscous media in a static situation, an “as machined” or “as cast” surface finish is unlikely to be sufficient for a polymer seal. Some form of post-process surface treatment will almost always be necessary.

Processes such as grinding, honing, polishing, and lapping can achieve the required finish, though these add significant cost to hardware. Depending on the configuration, polishing the inside of a groove deep inside a housing may be very challenging. It’s usually easier to get better finishes on rod surfaces rather than bores.

Therefore, given the option, it’s typically better to keep the dynamic sealing surface on a rod or shaft.

Cost–Benefit Analysis of Surface Finishing for Polymer Seals

Surface finishing can significantly impact both the cost of hardware and the reliability of the seal. For many projects, engineers must decide whether the added expense of finishing operations is justified by the performance benefits.

For example:

- In a general industrial application where a small amount of leakage is acceptable, a turned surface at ~32 µin Ra may perform adequately.

- In aerospace or medical devices, however, where leakage tolerance is close to zero, investing in polishing or lapping can mean the difference between mission success and costly failure.

The decision often comes down to risk versus return. Investing in better finishes increases upfront manufacturing cost but reduces the risk of failure, downtime, or warranty claims.

At Eclipse, we work with customers to assess the acceptable level of leakage for their application and recommend the most cost-effective surface finish that still ensures reliability.

Surface Treatment Methods to Improve Seal Performance

When a machined or cast surface doesn’t meet the finish requirements for PTFE or polymer seals, additional surface treatments can dramatically improve sealing performance.

Common post-processing methods include:

- Grinding: Achieves finishes down to 8 µin Ra, ideal for shafts and rods.

- Honing: Creates crosshatched bore surfaces that improve lubrication and wear resistance.

- Polishing: Delivers ultra-smooth surfaces, critical for medical, cryogenic, or semiconductor sealing.

- Lapping: Provides some of the smoothest finishes possible (sub-1 µin Ra), used in aerospace and high-vacuum systems.

The right treatment depends on geometry, media, and system dynamics. Each method adds cost, but when balanced correctly, they provide the performance improvements needed to ensure long-term sealing success.

What is Acceptable Leakage?

It’s important to note that surface finish recommendations can vary greatly depending on specific applications. Surface finishes may need to be more or less stringent based on the leakage goals of the system.

While any polymer seal will likely never achieve a “zero leak” situation despite the best surface conditions, it can be expected that the better the finish, the tighter the leakage control.

This is not always the case with O-Rings, where finishes that are too smooth can actually hurt sealing performance and significantly increase friction in dynamic situations.

Generally, with PTFE or polymer-based seals, the finishes “can’t be too good.”

But as stated earlier, achieving highly polished surfaces in certain hardware configurations can be very costly. It’s up to you to determine if the cost of achieving these finishes is needed to meet the goals of the application.

Eclipse has many customers who use finishes worse than recommended because leakage isn’t critical. For example, a customer constructing a standard air cylinder might typically use O-Rings for all primary seals.

In cases where operating temperature is too high for O-Rings, they may use an Eclipse PTFE spring-energized seal. Here, improving hardware finishes isn’t necessary, because slightly more leakage only results in a small decrease in efficiency — an acceptable tradeoff.

On the other end of the spectrum, finishes might need to be much better than recommended in critical sealing applications.

For example: a spring-energized seal used to contain cryogenic propellants on long-term space exploration missions. Any leakage here represents a mission limitation and liability. In this case, special techniques and materials might be necessary to provide the best finish possible.

The Future of Surface Engineering in Sealing Applications

Advancements in manufacturing are opening the door to new ways of achieving the ultra-smooth surfaces required for high-performance polymer seals.

Emerging approaches include:

- Laser Surface Texturing (LST): Controlled micro-patterning to reduce wear and enhance lubrication.

- Plasma Surface Treatments: Altering surface chemistry to reduce friction and improve sealing compatibility.

- Additive Manufacturing (3D Printing) Finishing: Post-processing techniques such as abrasive flow machining or electro-polishing that transform rough 3D-printed parts into seal-ready components.

- Diamond-Like Carbon (DLC) Coatings: Thin coatings that improve wear resistance, reduce friction, and create smoother interfaces.

These methods, once limited to aerospace or semiconductor industries, are becoming more accessible across sectors like energy storage, medical devices, and industrial machinery.

Eclipse stays at the forefront of these advancements, helping customers leverage modern surface engineering methods to achieve sealing success without excessive cost or complexity.

Eclipse Is Here to Help

Eclipse understands the implications of requiring polished surface finishes and that these kinds of operations are not always possible. We’re here to utilize our vast selection of seal materials and our decades of experience in seal design to provide a solution to even the most challenging applications.

For example, Eclipse had a customer looking for a seal for a large, heavy chamber door. The groove for the seal was a milled surface, and it would not be practical — or even really possible — to remove the door and perform a polishing process to improve the finish.

By careful seal material selection and unique design characteristics, we were able to provide a sealing solution that met their leakage requirement goals.

While recommendations are useful guidelines and starting points, they are not necessarily the end of the story. Contact Eclipse today to put our advanced knowledge base and manufacturing expertise to work for your most difficult sealing challenges.