Over the years, Eclipse has designed and manufactured sealing solutions for media ranging from mud to processed cheese to chemicals with names no one can pronounce and most everything in between.

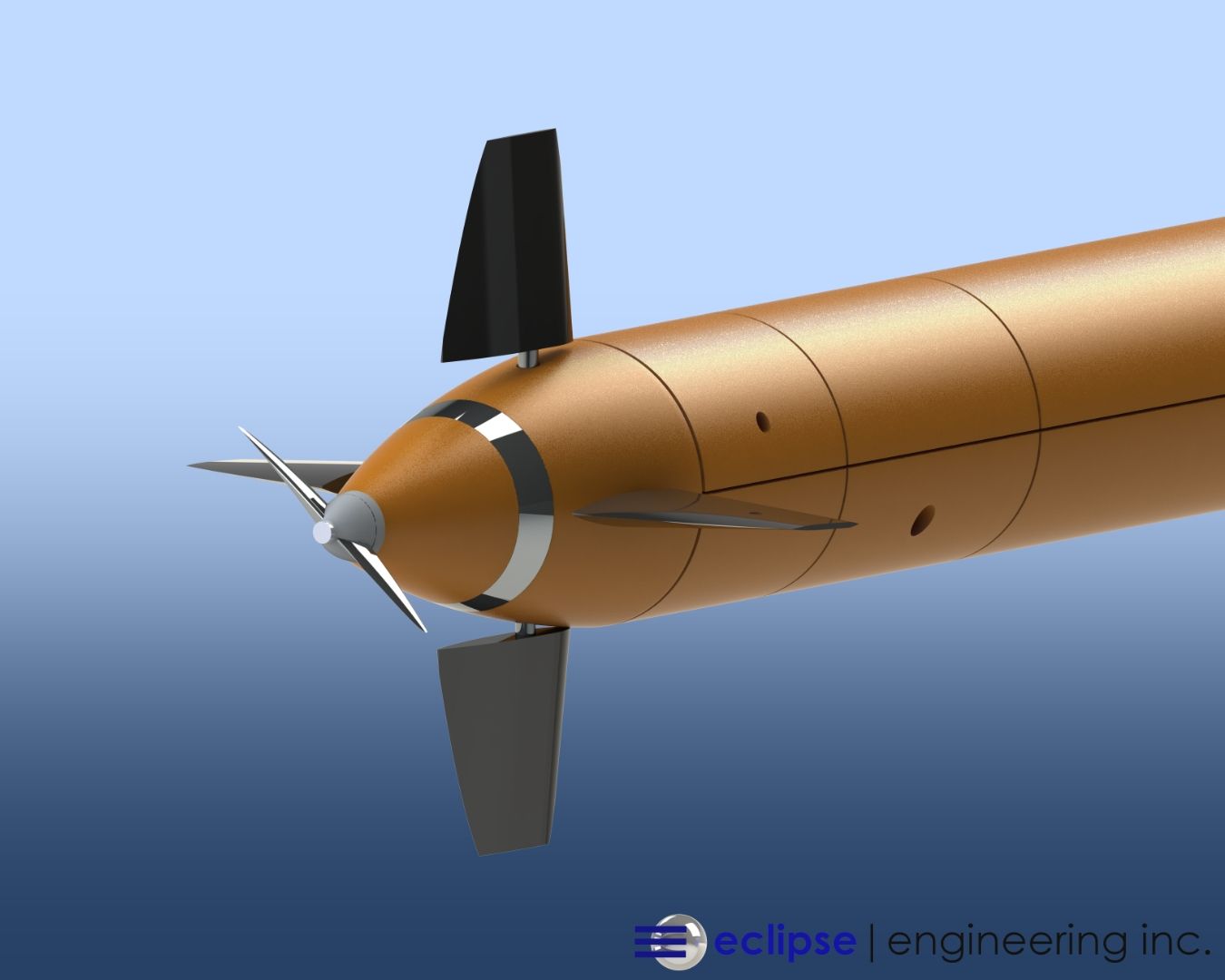

By far, one of the most challenging media to seal is the first element on the periodic table, Hydrogen. Its extremely small molecule size and the fact that sealing needs to be done at cryogenic temperature present difficulties for all seal designs and materials.

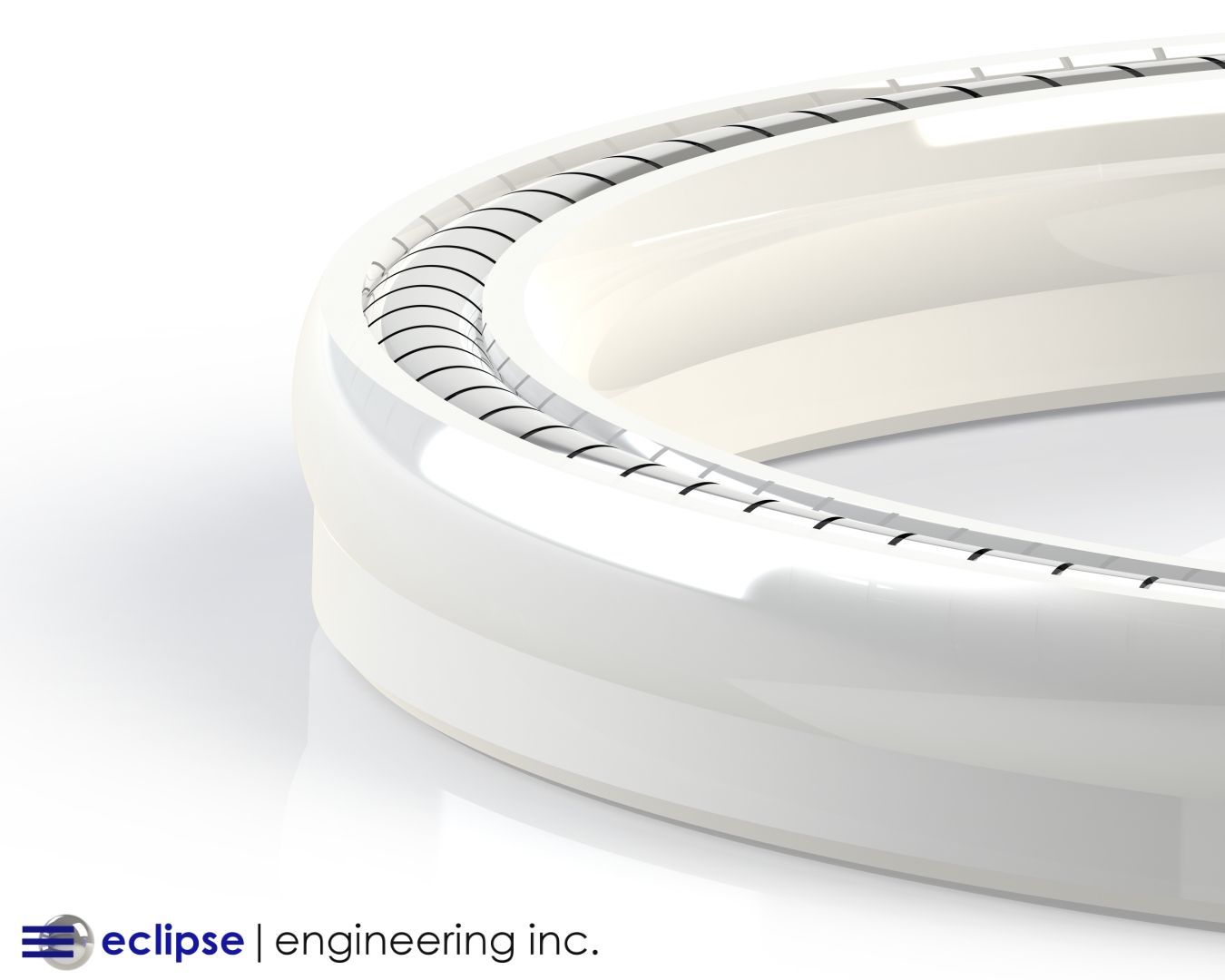

While Eclipse’s

Spring Energized Seals regularly perform under these operating conditions, the extremely stringent leakage requirement needed by the customer presented Eclipse with a unique challenge. Normally, such tight leakage constraints are achieved with the use of very soft and compliant seal materials such as specialized O-Rings or Thermoplastic Elastomers.

But the extreme temperature range and friction requirements of the valve meant that the use of soft, highly sealable materials would not be possible.

Polymer Superfinishing

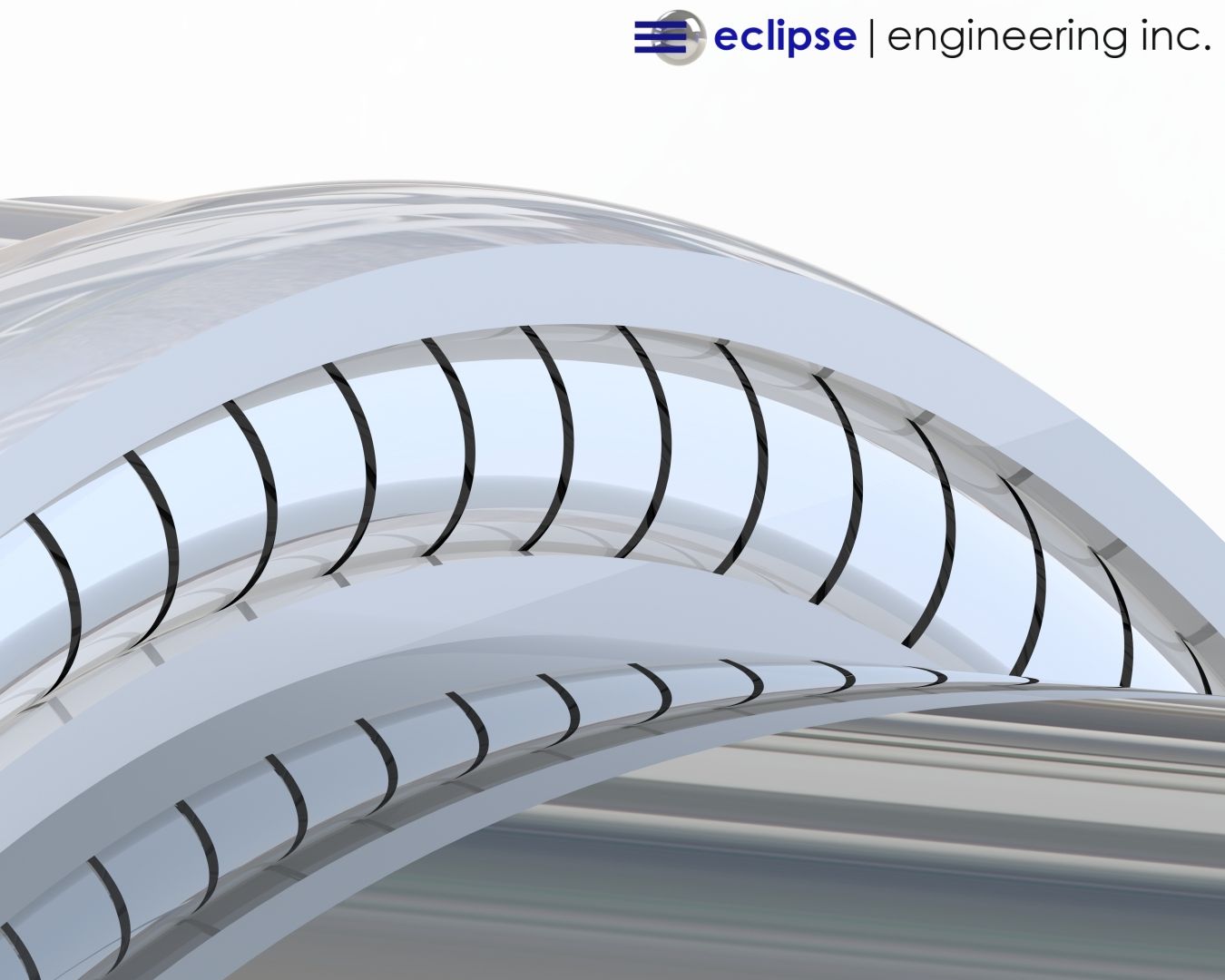

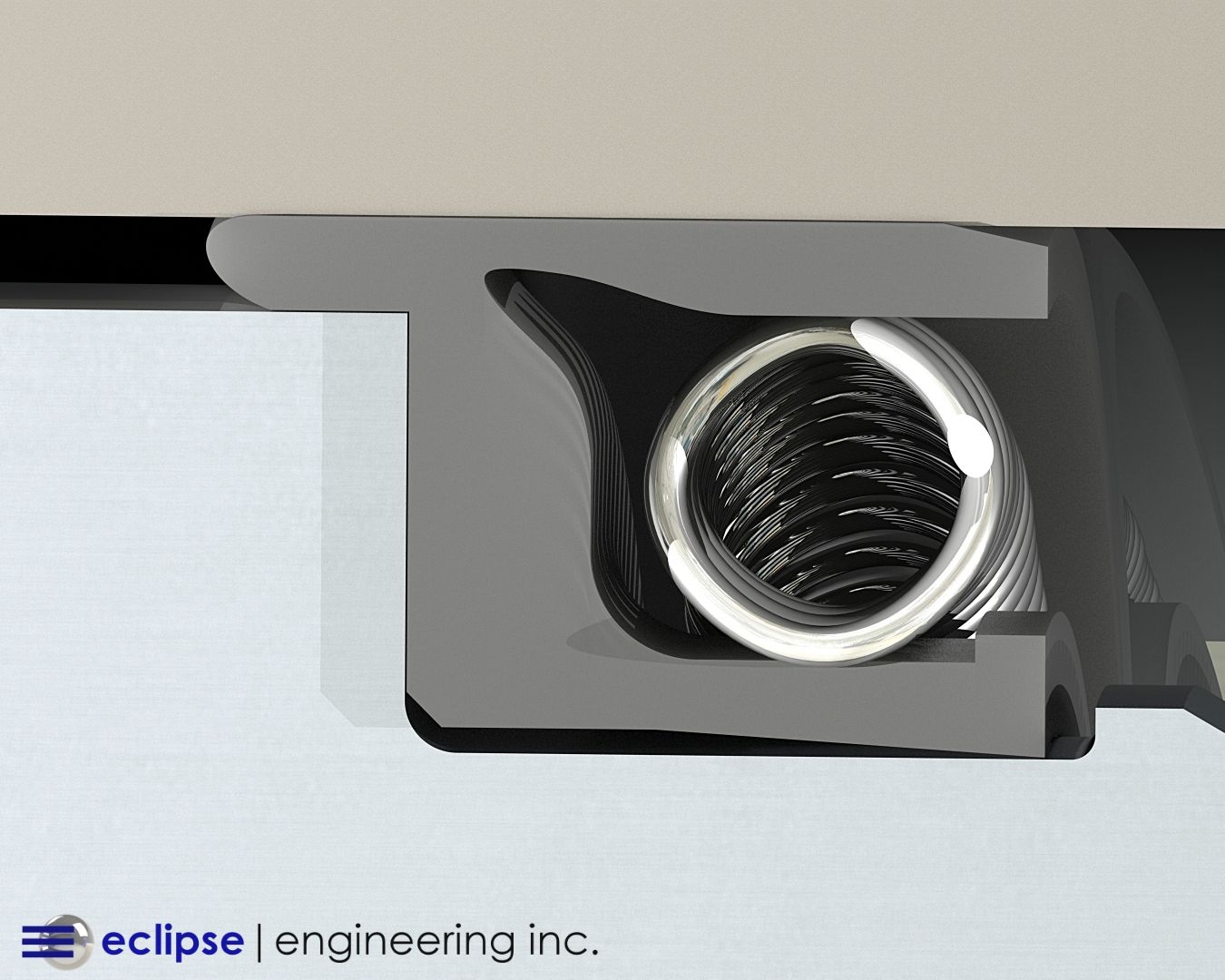

Eclipse knew that the application parameters meant the use of a PTFE based seal material would be required. Eclipse also knew that a typical, standard PTFE spring energized seal would not meet the customer’s leakage requirement. Eclipse turned their attention to surface interaction between the seal lip and hardware surface. If the seal lip and hardware surface finish could be optimized to exceedingly high levels then the permeability of the Hydrogen between the mating interfaces could be greatly reduced.

Superfinishing has been a technique used on metals for many years, but methods used for metals don’t typically translate or work well for polymers. Eclipse’s in-house manufacturing and design team developed both special tooling and techniques to provide a similar superfinish on PTFE based seal materials.

Eclipse’s many years’ worth of PTFE machining experience was key in developing and making this technique production ready.

Optimizing PTFE Machining with Eclipse’s EZ030 Technology

It might be easy to think that machining plastic would be less difficult than steel or metallic materials, but anyone who has tried probably quickly found out it’s not the case. Eclipse grinds much of its own tooling and utilizes cutting inserts out of high-speed steel, carbide, and diamond.

Eclipse developed special large-radius tooling to aid in the finishing. From there, “speeds and feeds” were adjusted in the CNC until the best finish was possible was achieved. While taking more time than standard machining techniques, the gains in the end were well worth it.

To further improve sealability performance, Eclipse used its

EZ030 modified PTFE. EZ030 is the unfilled variant of our enhanced PTFE. It retains all the advantages of standard PTFE, including chemical compatibility, friction properties, and temperature range. The key benefit of this modified version is its improved material adhesion during processing, which leads to a denser final structure. This denser structure enables EZ030 to achieve superior machined finishes on seals and offers enhanced permeation resistance. Consequently, it provides an unparalleled seal for use in gaseous media such as oxygen, hydrogen, nitrogen, and natural gas.

Eclipse’s effort in developing the superfinish technique, combined with the excellent properties of EZ030, resulted in a seal that met both the customer’s tough leakage requirement and life cycle targets.

If you have an application that can benefit from Eclipse’s superfinishing technique, please contact us today.