SERVICES

ENVIRONMENTAL & INDUSTRIAL SERVICES

ENVIRONMENTAL & INDUSTRIAL SERVICES

Since 1963, railroads and industry have placed their confidence in Hulcher. We have a staff of environmental professionals who are trained and experienced in a broad range of skills needed for large scale remediation projects, decommissioning and cleaning of tanks and industrial maintenance as well as emergency response work.

Hulcher maintains a continuous training program for all of our field personnel. Our interdisciplinary approach and training allow us to be cross-utilized in areas such as project management, health sciences, regulatory liaison, analytical data interpretation, permitting, heavy equipment mobilization and field supervisor duties. Employees complete a required hazardous materials awareness course when hired as well as an annual refresher course.

Our standard training programs includes, but is not limited to, the following courses:

- 1st Responder Operations Level (Hazmat)

- 40-Hour Hazmat Certification (HAZWOPER)

- 8-Hour Hazmat Annual Refresher

- Confined Space Entrant, Attendant and Supervisor

- Fall Protection

- Heat Stress

- Lockout/Tagout (LOTO)

- Monthly Chemical Training

- Personal Protective Equipment (PPE) and Respiratory Protection

Whether it's product salvage and recovery from a derailment or transferring product from an overloaded hopper car, our crews are ready 24/7/365 when and where you need us. Call Hulcher at

833-316-0035

today to speak with one of our Field Support Specialists.

HULCHER ON THE JOB

Latest Newsfeed

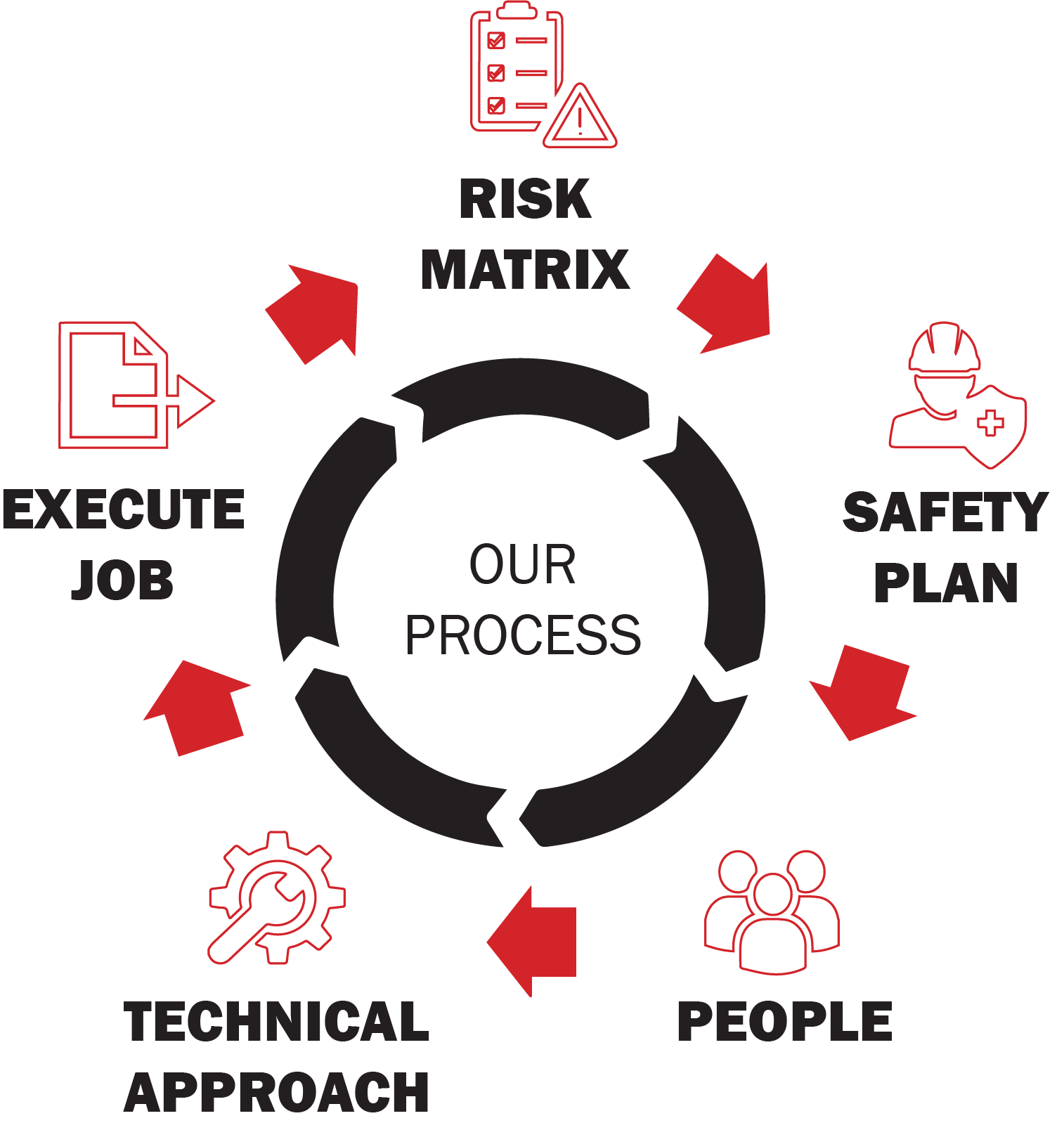

OUR PROCESS

PROJECT RISK MATRIX

- Project Work Schedule – GANTT chart detailing the projected start and end date for each phase of work.

- Initial Site Activities – Action items to be completed before Remediation work begins.

- Remediation Activities with Sequencing Plan

- Site-Specific Health & Safety Plan – In collaboration with Hulcher’s Safety Group, the written plan is reviewed with each employee BEFORE the project starts. Once work begins, a Job Safety Briefing is conducted daily with all Staff.

- Additional Safety Briefings are held as needed should conditions, equipment or personnel change during the day.

- Project Work Schedule – GANTT chart detailing the projected start and end date for each phase of work.

- Initial Site Activities – Action items to be completed before Remediation work begins.

- Remediation Activities with Sequencing Plan

- Site-Specific Health & Safety Plan – In collaboration with Hulcher’s Safety Group, the written plan is reviewed with each employee BEFORE the project starts. Once work begins, a Job Safety Briefing is conducted daily with all Staff.

- Additional Safety Briefings are held as needed should conditions, equipment or personnel change during the day.

- Project Work Schedule – GANTT chart detailing the projected start and end date for each phase of work.

- Initial Site Activities – Action items to be completed before Remediation work begins.

- Remediation Activities with Sequencing Plan

- Site-Specific Health & Safety Plan – In collaboration with Hulcher’s Safety Group, the written plan is reviewed with each employee BEFORE the project starts. Once work begins, a Job Safety Briefing is conducted daily with all Staff.

- Additional Safety Briefings are held as needed should conditions, equipment or personnel change during the day.

INDUSTRY EVENTS & TRADESHOWS

Please stop by the Hulcher Services booth to get a first hand look at the wide variety of innovative services and learn how we can help you keep your business on time and on target.

We're Hiring!

We're Hiring!

Have a project or question? Send us a message.

Contact Us

We will get back to you as soon as possible.

Please try again later.

Ready to discuss a project? Send us a message.

Have a project or question? Send us a message.

Contact Us

We will get back to you as soon as possible.

Please try again later.

OUR SERVICES

INDUSTRIES WE SERVE

OUR SERVICES

INDUSTRIES WE SERVE

© 2020 Hulcher Services Inc. All Rights Reserved.

© 2020 Hulcher Services Inc. All Rights Reserved.

© 2022 Hulcher Services Inc. All Rights Reserved.

Ready to discuss a project? Send us a message.

Contact Us

We will get back to you as soon as possible.

Please try again later.