CONVEYOR SYSTEMS

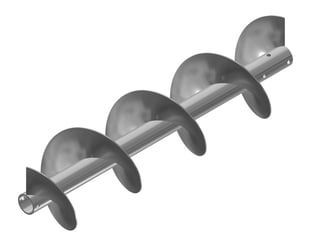

Screw conveyors, often referred to as augers, play a vital role in handling drill cuttings in the oil and gas as well as the civil construction industries. Drill cuttings must be efficiently transported to ensure safe drilling operations. Screw conveyors are designed for this task. Utilizing a rotating helical screw blade, usually within a trough, to move sludge or granular materials, these machines are a preferred choice for transferring drill cuttings from the shale shaker (the first phase of cleaning for the drilling fluids) to other equipment or disposal sites. Their inherent design allows them to handle semi-solid materials like drill cuttings efficiently, even when those materials are wet and sticky.

The use of screw conveyors in the oil and gas and civil construction industries offers several advantages. They are not only robust and reliable but also simple to install and maintain, making them ideal for the demanding environments typical of drilling operations. Due to their enclosed nature, screw conveyors also minimize the risk of spillage, helping to create safer worksites and reduce environmental impact. Additionally, their design makes it possible to move materials horizontally, vertically, or at an incline, providing the flexibility needed in various drilling scenarios. By employing screw conveyors, companies in these industries can ensure effective management of drill cuttings, thereby enhancing operational efficiency and compliance with environmental regulations.