SHAKERS

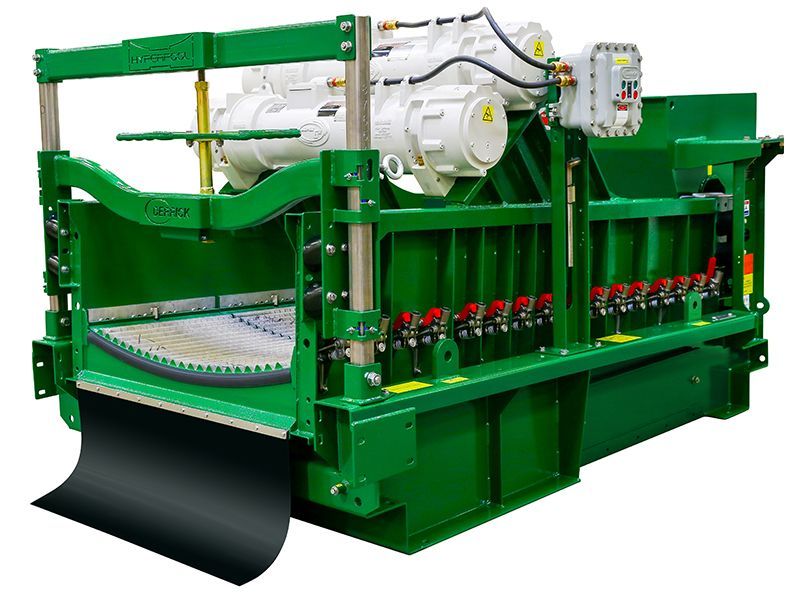

Shaker units are integral tools within the oil and gas and civil construction industries, playing a crucial role in the field of solids control. In drilling operations, a shaker is a vibrating device designed to separate drill cuttings, or solid particles, from the drilling fluid, commonly referred to as mud. As the drilling fluid, laden with cuttings, is returned from the well, it is fed onto the vibrating screen of the shaker. The liquid portion of the mud and smaller particles pass through this screen, while the larger solids are effectively separated and discarded. This process is essential as it facilitates the recycling of valuable drilling fluid, reduces the volume of waste material, and helps to prevent potential damage to drilling equipment.

Shaker units are notable for their high-performance and advanced design, often featuring multiple screens that increase their capacity and efficiency in comparison to traditional shaker systems. Their compact dimensions are also advantageous, especially on drilling sites where space is limited. In the oil and gas industry, these shaker units are utilized in both onshore and offshore drilling operations, offering reliable and effective solids control to ensure smooth drilling processes. Within the civil construction sector, shaker units are commonly employed for various tasks such as piling, micro-tunneling, and other sub-surface excavation procedures where effective management of excavated soil and groundwater is paramount. By ensuring efficient solids control, shaker units contribute significantly to the productivity, safety, and environmental compliance of drilling operations across these industries.

SHAKER ENQUIRY